During the Open Source Hardware week of Fabricademy 2023/2024, the students worked on a first hack of the Shopbot in the Fablab. The students had a week (!) to develop the hack and document their findings. Their work this week formed the starting point for our future machine hacking development.

In the slides below you can find the outcomes of this intensive collaborative project.

They also made a video of their process.

Team

Each member documented their contribution on their respective Fabricademy documentation blog. If you click their names you can find their documentation. Aslı Aydın Aksan was both instructor and student this week.

Work was divided as follows:

| Hardware | Stephanie Johnson & Aslı Aydın Aksan |

| Electronics | Riley Cox & Michelle Vossen |

| Brush Design | Jiawen Gong & Ray Formilli |

| Ink / Surface | Ray Formilli & Jiawen Gong |

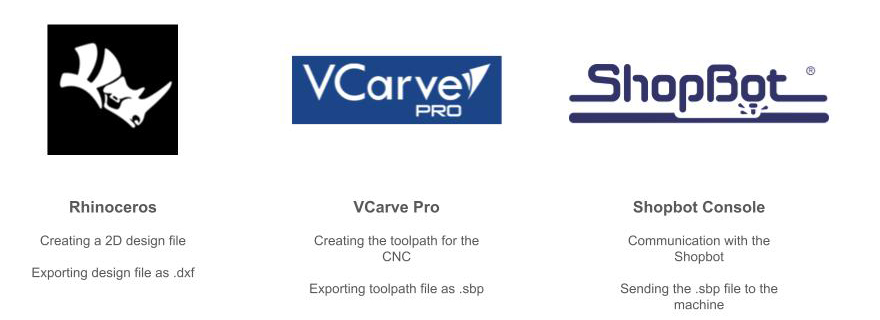

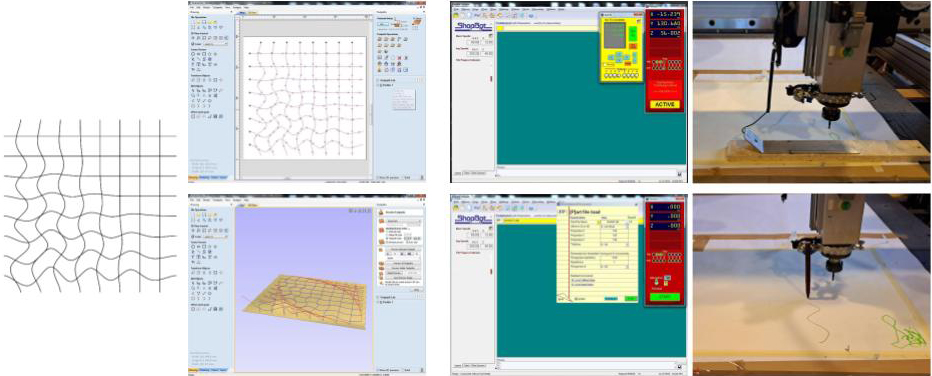

| CNC / sbp code / design files | Aslı Aydın Aksan & Jiawen Gong |

| Documentary | Ray Formilli & Machteld Zee |

| Project Management | Machteld Zee & Michelle Vossen |

They did extensive research into the elements that dictate the basic parameters of the printing action, that also form core areas for our pilot research. Some highlights from their research can be seen below.

- Machine code (by Aslı):

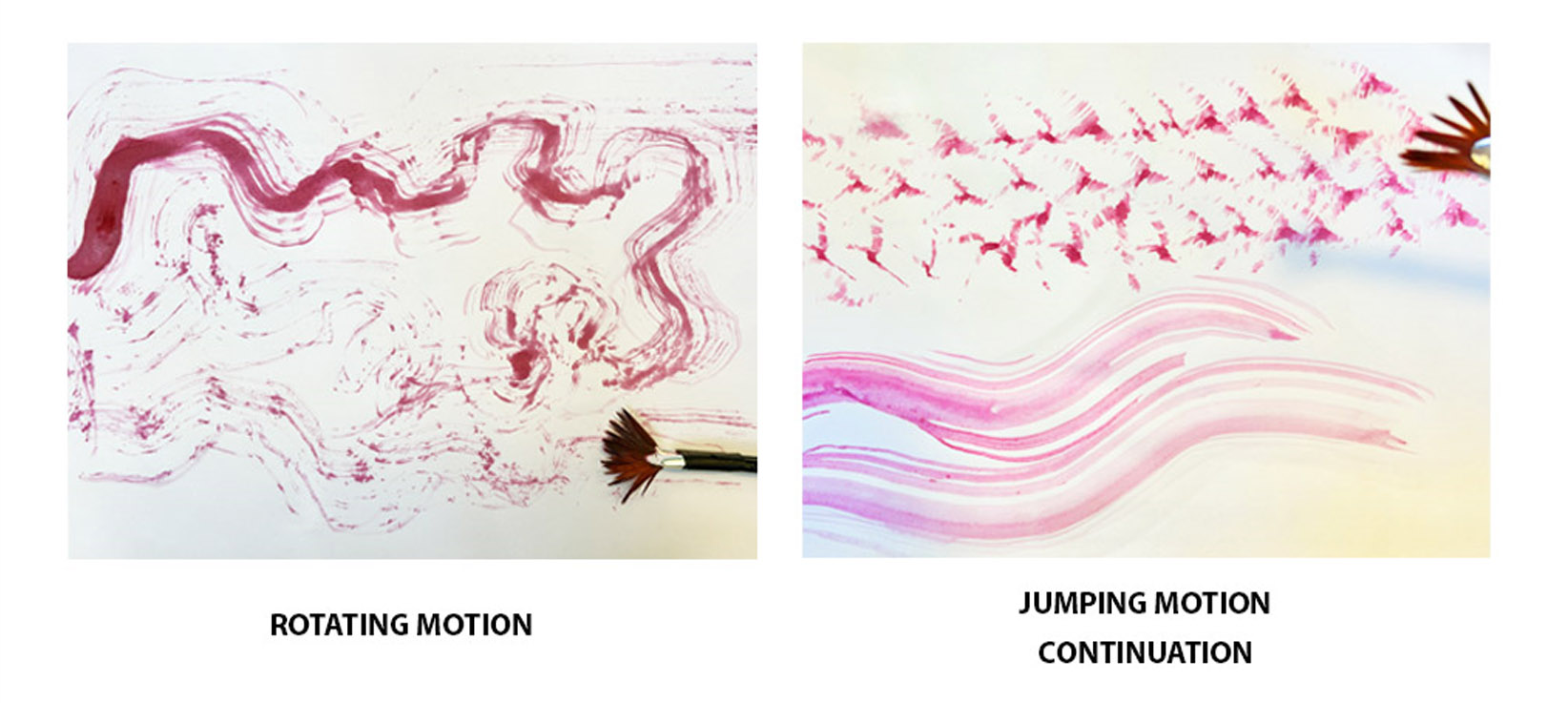

- Tools, mediums and brush motion (by Jiawen and Ray):

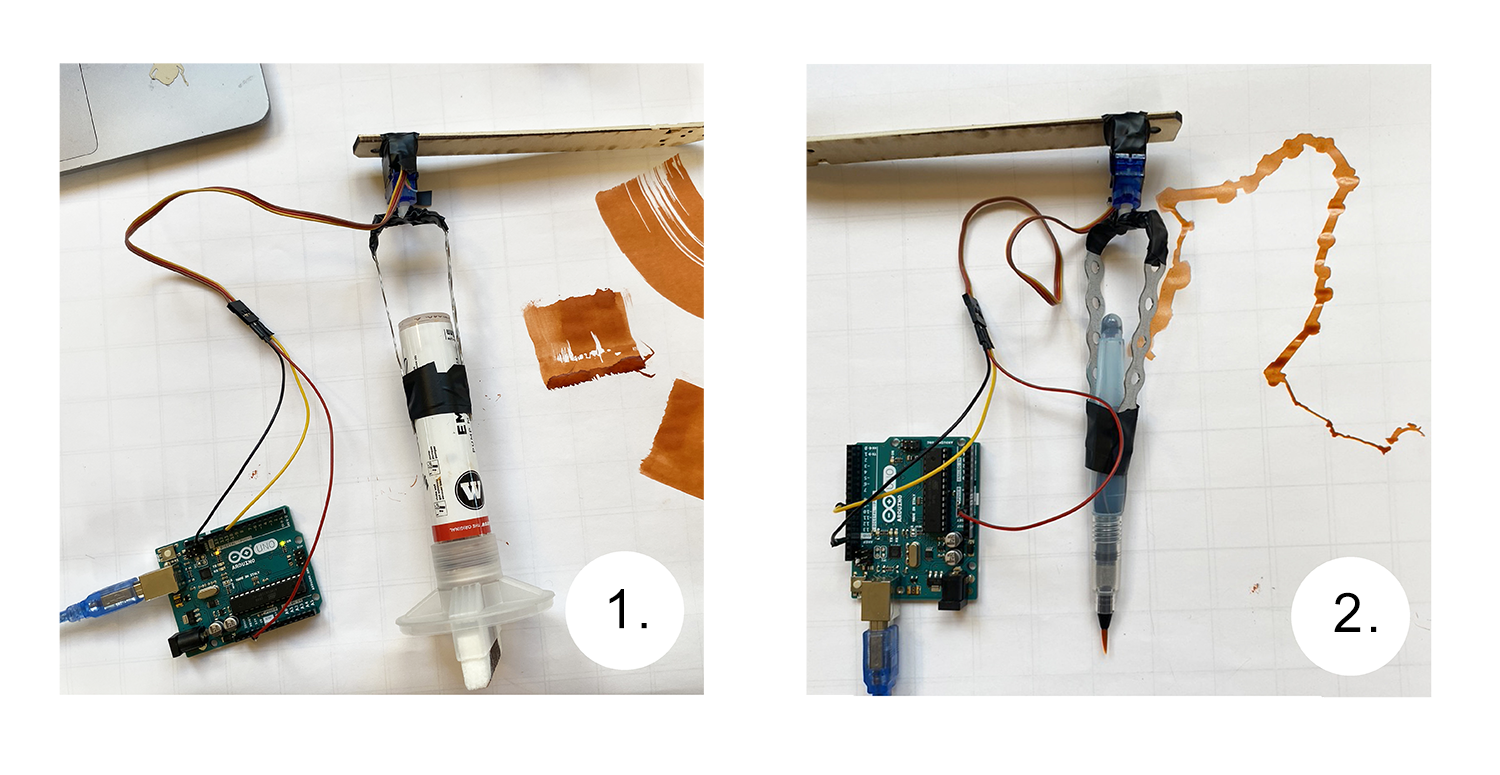

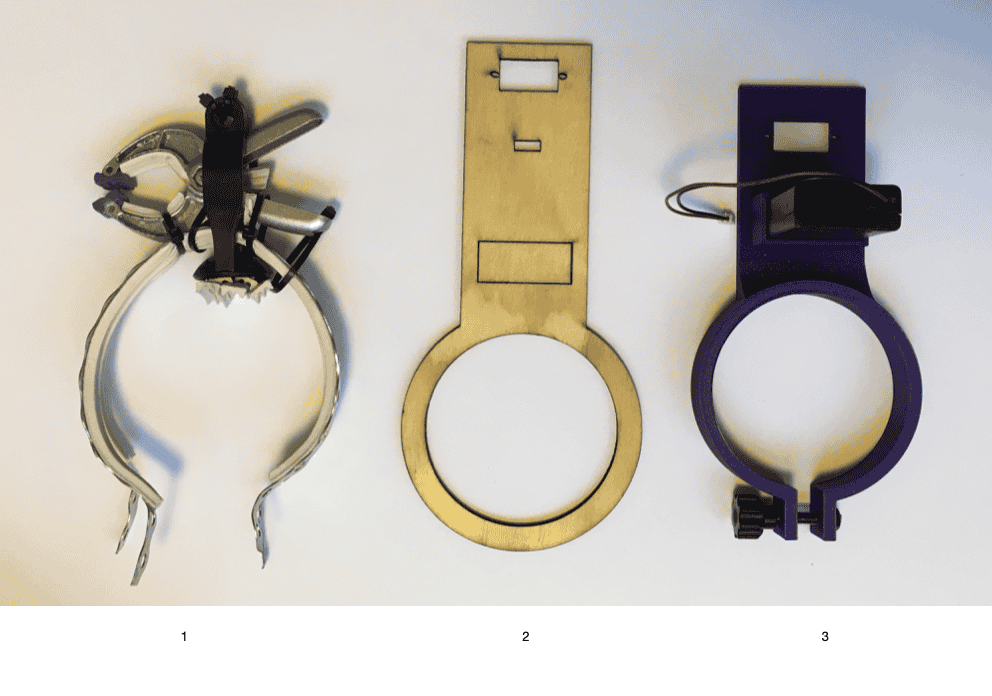

- Tool holder & electronics development (by Riley):

- Machine attachment development (by Stephanie):

About Fabricademy

Fabricademy, Textile and Technology academy is a multidisciplinary 6-month intensive program at the intersection of digital fabrication, textiles and biology. The program explores the interrelation of human-technology-environment through the notions of embodiment, materiality, ecodesign, biodesign, performance, smart textiles and digital fabrication. Our mission is to (re)shape and (re)define the implications and applications of technology in the textile and clothing industry, from the fashion sector to the upcoming wearable market. The program offers a broad overview of the state of the art of the current industry and builds on “learning by doing” methodologies, tackling themes like personal fabrication, distributed manufacturing, industry 4.0, wearable technology, biofabrication, assistive technologies and sustainability. (via https://fabricademy.org)